“As a seasoned EPC (Engineering, Procurement, and Construction) company, we’ve spent years specifying, integrating, and building concrete batch plant systems for clients across the industry. Through hands-on facility construction and close collaboration with plant operators, maintenance teams, and production managers, we've gained a deep understanding of what works and what doesn't in the field.

Every component reflects lessons learned from real-world operations, with design decisions shaped by direct end-user feedback. The result is a high-capacity, operator-informed batch plant that delivers durability, efficiency, and practical serviceability from the ground up.”

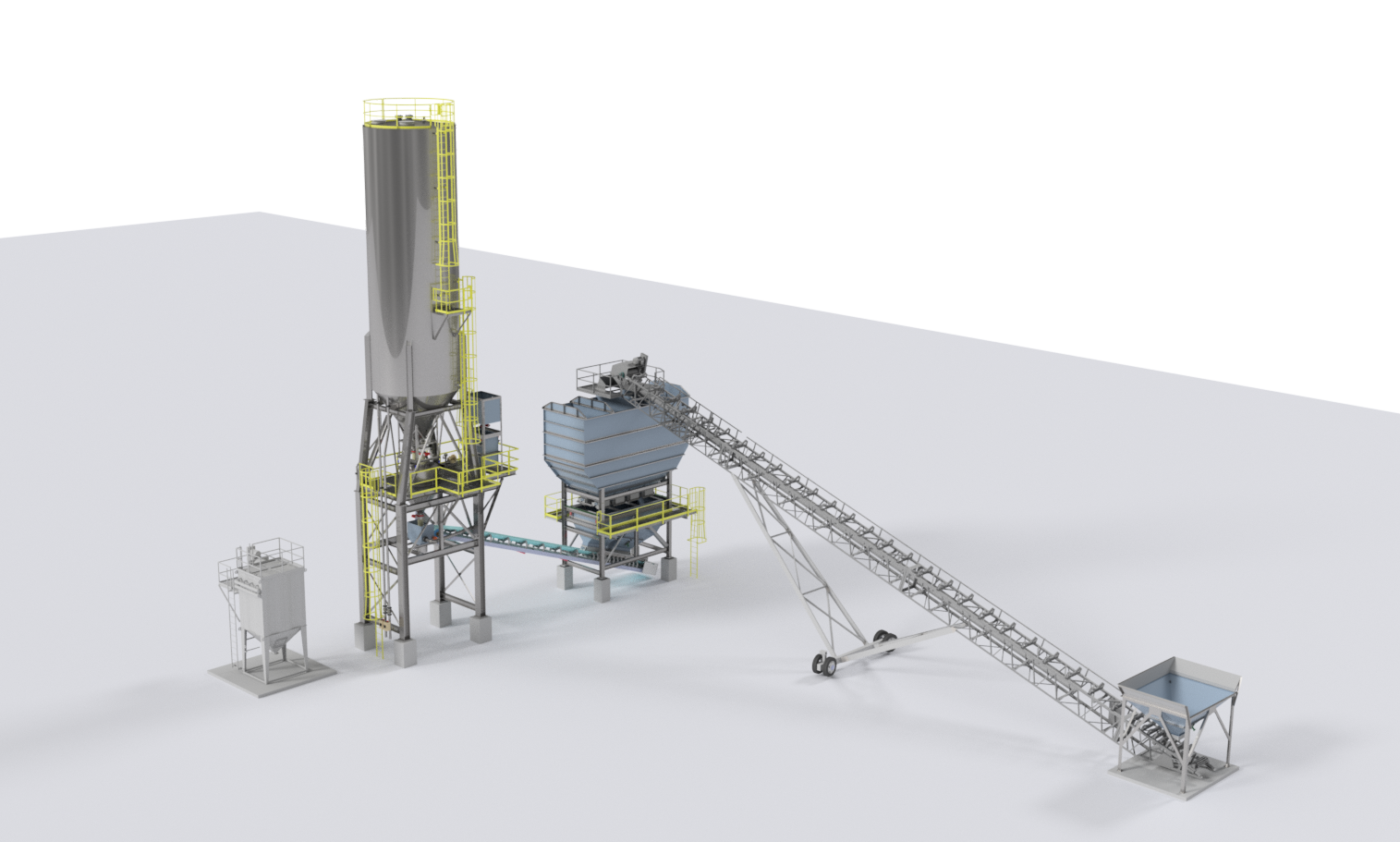

BATCH PLANT OVERVIEW

As part of our comprehensive batch plant solutions, Trident provides integrated, durable, and operator-friendly systems designed for efficient concrete production. Leveraging real-world insights, every batch plant is engineered to optimize performance, minimize downtime, and ensure ease of maintenance.

High Production Capacity

Output from 100 to 200+ yd³/hour, scalable as needed

Modular & Customizable Design

Configurations tailored to customer needs,

One-Stop EPC Turnkey Delivery

Full lifecycle delivery from civil work to startup, with single-source accountability, reduced vendor coordination, and faster commissioning.

Heavy-Duty Aggregate Handling System

30–36” wide belts, high-speed shaft-mounted reducers

Aggregate Bins/Batchers

Bins (up to 200 tons) and batchers (12 yd³ capacity)

Flexible Cement Storage Solutions

Split or dual silos (400–1200 BBL) for multiple cement or fly ash types, with aeration, fill-level monitoring, and emergency slide gates.

Integrated Water Management

450-gallon water batchers and 500-gallon surge tanks

Smart Automated Controls

(Jonel System) Centralized automation

Operator & Maintenance Accessibility

Full-service platforms, ladders, and handrails for safety

Compliance Ready

Designed to meet OSHA and NRMCA standards